企业免费推广平台

布料幅宽:1.7米、2.05米、2.4米、2.8米、3.2米可选

布料转速:0-800 (转/分钟)

切布直径:300毫米,也可定制400毫米、500毫米、600毫米

布轴直径:37毫米 布料电机功率:0.75千瓦

刀片电机功率:1.5千瓦

最小切条宽度:2毫米

电压:380V/220V可选

外形尺寸:1.7门幅为2.8米x0.85米x1.5米 600最大长度不超过3.5米

1、 主轴以及圆刀使用无级变速系统,可做高低无级调速及正反转切换控制。

2、 台板左右移位和进退刀均采用进口高精密步进系统及进口PLC控制切割宽度及进退刀切割和磨刀系统,配合进口精密滚珠丝杆及滑轨移位,高寿命,不易磨损,使切割宽度的精度达到0.1毫米,最窄切割宽度为2毫米,进刀切割时平行快速推进,速度采用无极调速,可分段控制,纸管容易切断,达到高精度快速切出高品质的产品。

3、 操作界面采用电脑触摸屏,所有操作,只需要一个画面,可同时设定六种分切宽度和次数,并显示实际切割次数,并设有手动/自动转换及磨刀手动/自动转换功能。

4、 在手动功能下,设有十字摇杆手柄,操作更加人性化!更加便捷,移动速度更快,移动的同时,可以在触摸屏上显示移动的宽度,达到更加精准。

5、 配备数控自动双面磨刀系统,电脑控制砂轮,自动进退,并根据刀片大小自动定位,可设定磨刀次数及时间,自动启动旋转,自动停止,采用金刚石砂轮磨削,经久耐用,不易发热,刀片磨后光洁度高,使用寿命是普通白玉刚砂轮的十倍,刀片不用拆卸,即可磨刀。刀片长期保持锋利,达到最佳裁切质量,并附有自动吸尘装置,保持布料及轨道清洁。

6、 采用快速放料设计,一步到位。上料下料只须一个动作即可完成。

7、 电路采用各个独立控制系统,每条线都做有标号,诊断维修简单快捷,不易出故障。

8、 夹布卡盘配有安全防护罩,不伤人。电线配有工程塑料链条保护,电线不容易折断,不容易老化。

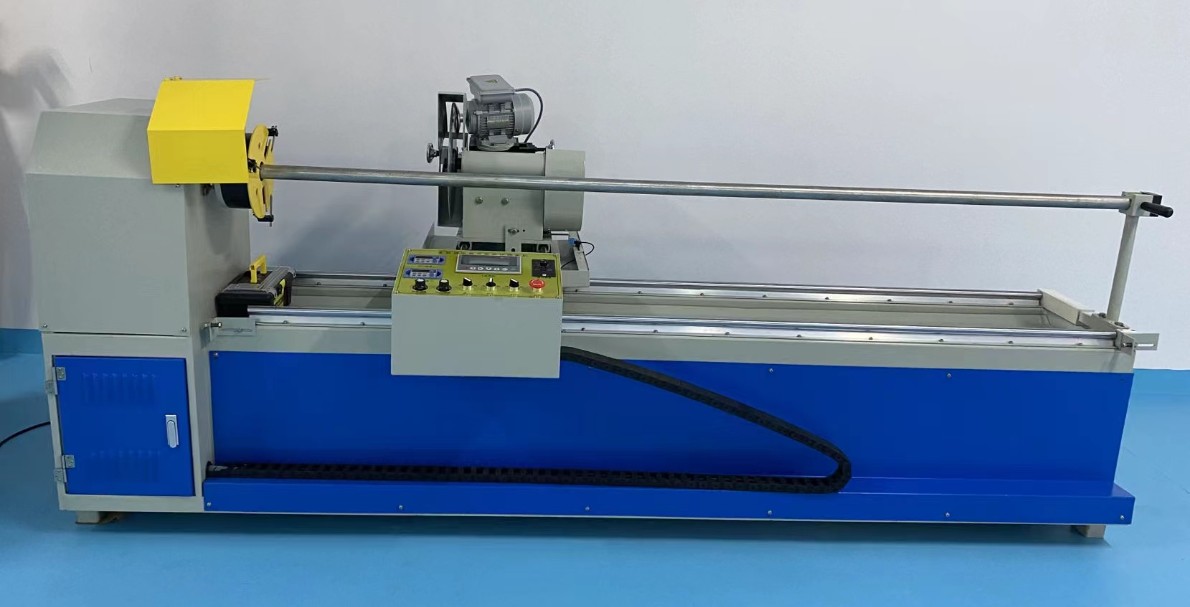

Technical parameters of dual CNC fully automatic cutting machine

Fabric width: 1.7 meters, 2.05 meters, 2.4 meters, 2.8 meters, 3.2 meters optional

Fabric speed: 0-800 rpm

Cutting diameter: 300mm, also customizable for 400mm, 500mm, 600mm

Fabric shaft diameter: 37mm Fabric motor power: 0.75 kW

Blade motor power: 1.5 kW

Minimum cutting width: 2mm

Voltage: 380V/220V optional

External dimensions: 1.7 door width: 2.8 meters x 0.85 meters x 1.5 meters, 600 maximum length not exceeding 3.5 meters

Equipment instructions for dual CNC fully automatic cutting machine

1. The spindle and circular cutter use a continuously variable speed system, which can perform high and low stepless speed regulation and forward and reverse switching control.

2. The left and right displacement of the table and the forward and backward cutting are both controlled by imported high-precision stepper systems and imported PLC control cutting width, as well as the forward and backward cutting and grinding systems. Coupled with imported precision ball screw and slide rail displacement, it has a long service life and is not easy to wear, resulting in an accuracy of 0.1 millimeters in cutting width. The narrowest cutting width is 2 millimeters, and the feeding cutting is carried out in parallel and quickly. The speed is stepless speed regulation, which can be segmented and controlled. The paper tube is easy to cut, Achieve high-precision and fast cutting of high-quality products.

3. The operation interface adopts a computer touch screen, and all operations require only one screen. Six cutting widths and times can be set simultaneously, and the actual cutting times can be displayed. It is also equipped with manual/automatic conversion and grinding manual/automatic conversion functions.

4. Under manual function, there is a cross rocker handle, making the operation more user-friendly! It is more convenient, with faster movement speed. While moving, the width of the movement can be displayed on the touch screen, achieving more accuracy.

5. Equipped with a CNC automatic double-sided grinding system, computer controlled grinding wheel, automatic advance and retreat, and automatic positioning according to the size of the blade. The number and time of grinding can be set, and the rotation can be automatically started and stopped. Diamond grinding wheel is used for grinding, which is durable and not easy to generate heat. The blade has a high surface finish after grinding, and its service life is ten times that of ordinary white jade grinding wheel. The blade can be ground without disassembly. The blade remains sharp for a long time to achieve optimal cutting quality, and is equipped with an automatic vacuum device to keep the fabric and track clean.

6. Adopting a fast feeding design, it can be achieved in one step. Loading and unloading can be completed with just one action.

7. The circuit adopts various independent control systems, and each line is labeled. Diagnosis and maintenance are simple and fast, and faults are not easy to occur.

8. The cloth clamping chuck is equipped with a safety protective cover, which does not harm people. The wires are equipped with engineering plastic chains for protection, making them less prone to breakage and aging.

本站提醒: 以上信息由用户在商名网发布,信息的真实性请自行辨别。服务协议 - 信息投诉/删除/联系本站

石狮市布加里精密制造厂 Copyright © 商名网营销建站平台 All Rights Reserved.